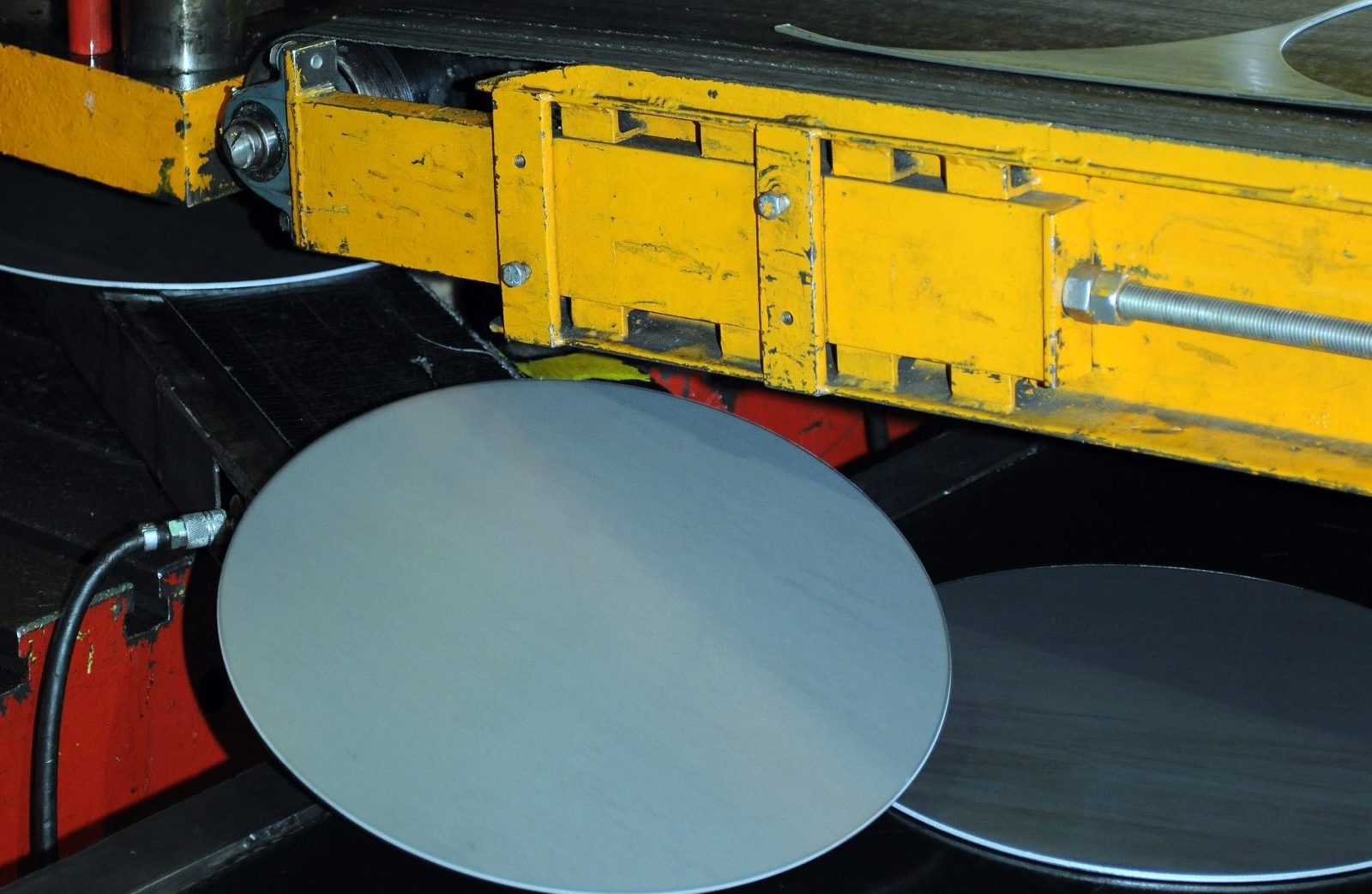

Blanking

Blanking is precision at its finest, delivering steel cut to exact dimensions and ready for fabrication. At Heidtman Steel, our state-of-the-art blanking processes ensure consistency, efficiency, and quality, tailored to meet the specific needs of industries like automotive, appliance, and manufacturing.

About This Process

Blanking is a precision steel-cutting process that transforms steel sheets or coils into specific shapes, known as blanks, with tight tolerances. At Heidtman Steel, this technique ensures minimal waste and high accuracy, making it ideal for industries requiring consistent, ready-to-use steel components.

- Cuts steel sheets or coils into precise shapes with clean edges.

- Supports tight tolerances for demanding applications like automotive and appliances.

- Accommodates various steel types, including coated and high-strength materials.

- Enhances efficiency by delivering parts ready for further manufacturing.

Capable Locations

Min/Max Capability

.020 to .500

Key Characteristics

- Precision Cutting: Produces steel blanks with consistent dimensions and clean edges.

- Material Versatility: Compatible with a wide range of steel grades and coatings.

- Cost Efficiency: Minimizes scrap and reduces additional processing time.

- High Volume Capabilities: Ideal for industries requiring large quantities of identical parts.

How is it Done?

- Material Feeding: Steel coils or sheets are fed into a blanking press or die.

- Cutting: The material is cut into predetermined shapes or sizes using a die or shear.

- Inspection: Blanks are checked for dimensional accuracy and surface quality.

- Stacking: Finished blanks are stacked and prepared for delivery or further processing.

Common Applications

- Automotive Industry: Structural panels, brackets, and stamped components.

- Appliance Manufacturing: Steel blanks for washers, dryers, and refrigerators.

- Construction: Pre-cut steel pieces for framing, roofing, and custom components.

- Electrical Components: Steel blanks used in enclosures and assemblies.

Benefits

- Reduces Waste: Cuts material precisely, minimizing scrap and optimizing usage.

- Speeds Up Production: Provides parts that are ready for the next manufacturing step.

- Improves Consistency: Ensures all blanks meet exact specifications.

- Customizable Solutions: Tailored blanking options to fit your unique production needs.

Why Choose Blanking?

Blanking provides the precision and efficiency needed for high-performance manufacturing. By delivering pre-cut steel tailored to exact requirements, this process saves time, reduces waste, and ensures quality, making it a key step in industries where accuracy matters.