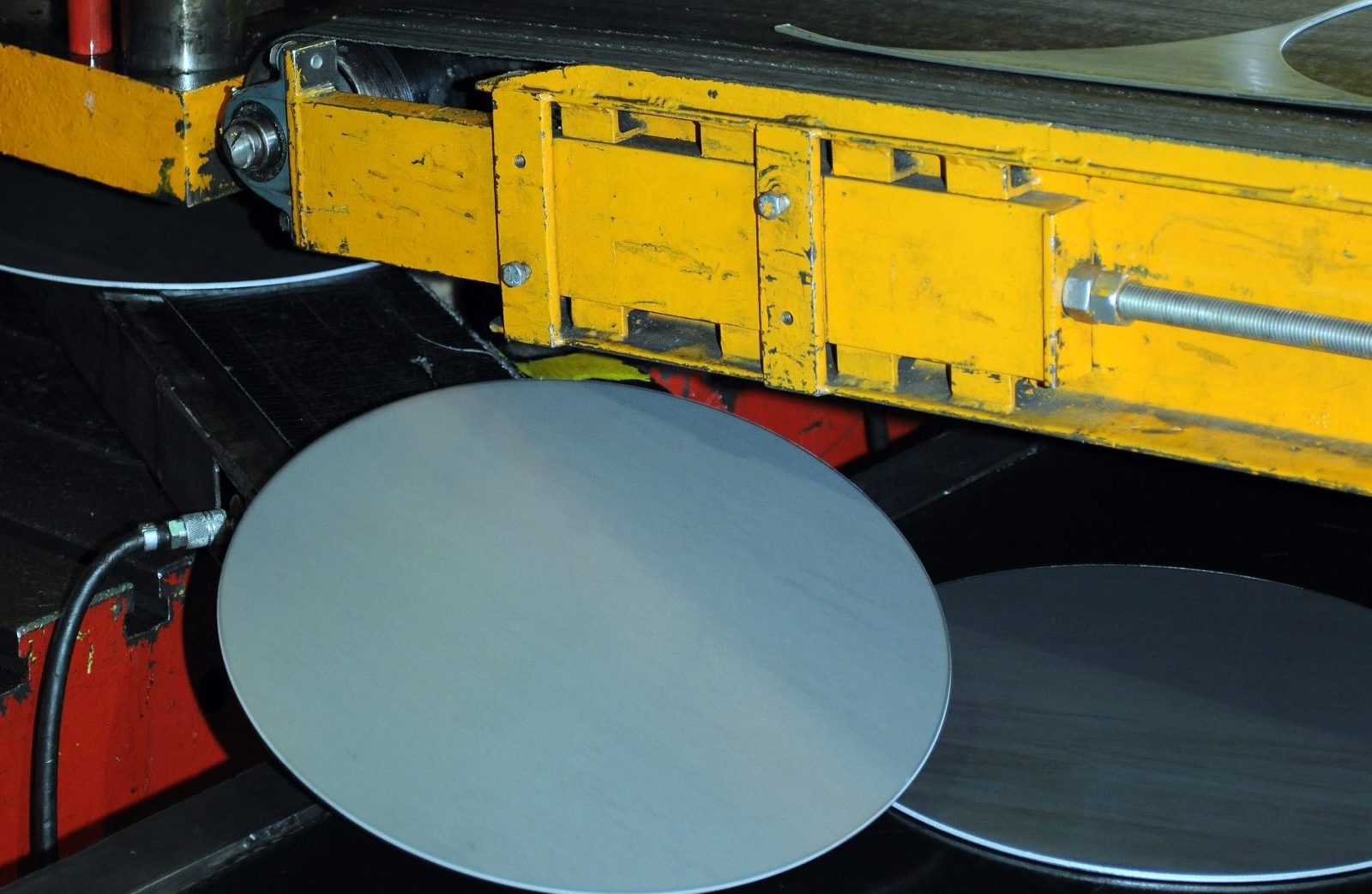

Shearing

Shearing delivers precision-cut steel tailored to your exact specifications. At Heidtman Steel, our advanced shearing process transforms sheets and plates into clean, accurately sized pieces with minimal waste, ensuring efficiency and quality—perfect for industries that demand reliable, ready-to-use steel components.

About This Process

Shearing is a steel processing method that uses precision blades to cut steel sheets or plates into smaller, specific sizes or shapes. This straightforward and efficient process trims edges, divides sheets, or creates custom blanks, delivering clean, straight cuts with minimal waste. Shearing is ideal for industries requiring accurately sized steel components ready for immediate use or further fabrication.

- Cuts steel sheets or plates into smaller pieces with precision blades.

- Produces clean, straight edges with minimal distortion.

- Efficiently trims excess material or divides large sheets into manageable sizes.

- Offers fast processing for high-volume production needs.

Capable Locations

Min/Max Capability

.015 to .500

Key Characteristics

- Precision Cutting: Delivers accurate cuts to meet tight dimensional tolerances.

- Clean Edges: Produces straight, burr-free edges suitable for downstream applications.

- Material Versatility: Effective for various steel grades, thicknesses, and coatings.

- High Efficiency: Rapid cutting process ideal for large-scale production.

How is it Done?

- Material Loading: Steel sheets or plates are positioned on the shearing machine.

- Alignment: The material is aligned to ensure precise cutting according to specifications.

- Shearing: A sharp blade descends or moves across the steel, slicing it cleanly into the desired size or shape.

- Collection: Cut pieces are collected, inspected for accuracy, and prepared for delivery or further processing.

Common Applications

- Automotive Industry: Blanks and trim pieces for body panels and structural components.

- Construction: Steel sections for framing, supports, and cladding.

- Appliances: Pre-cut steel for enclosures, brackets, and interior parts.

- Manufacturing: Custom-sized steel sheets or strips for stamping, forming, or assembly.

Benefits

- Accuracy: Provides precise cuts that meet exact size requirements.

- Minimal Waste: Efficient trimming and cutting reduce material loss.

- Speed: Fast processing enhances production timelines.

- Versatile Solutions: Suitable for a wide range of steel types and industrial needs.

Why Choose Shearing?

Heidtman Steel’s Shearing process offers a reliable, efficient way to transform steel sheets into precisely sized pieces with clean edges. Whether you need custom blanks or trimmed sheets, shearing delivers high-quality results that streamline your production process and ensure consistency across applications.