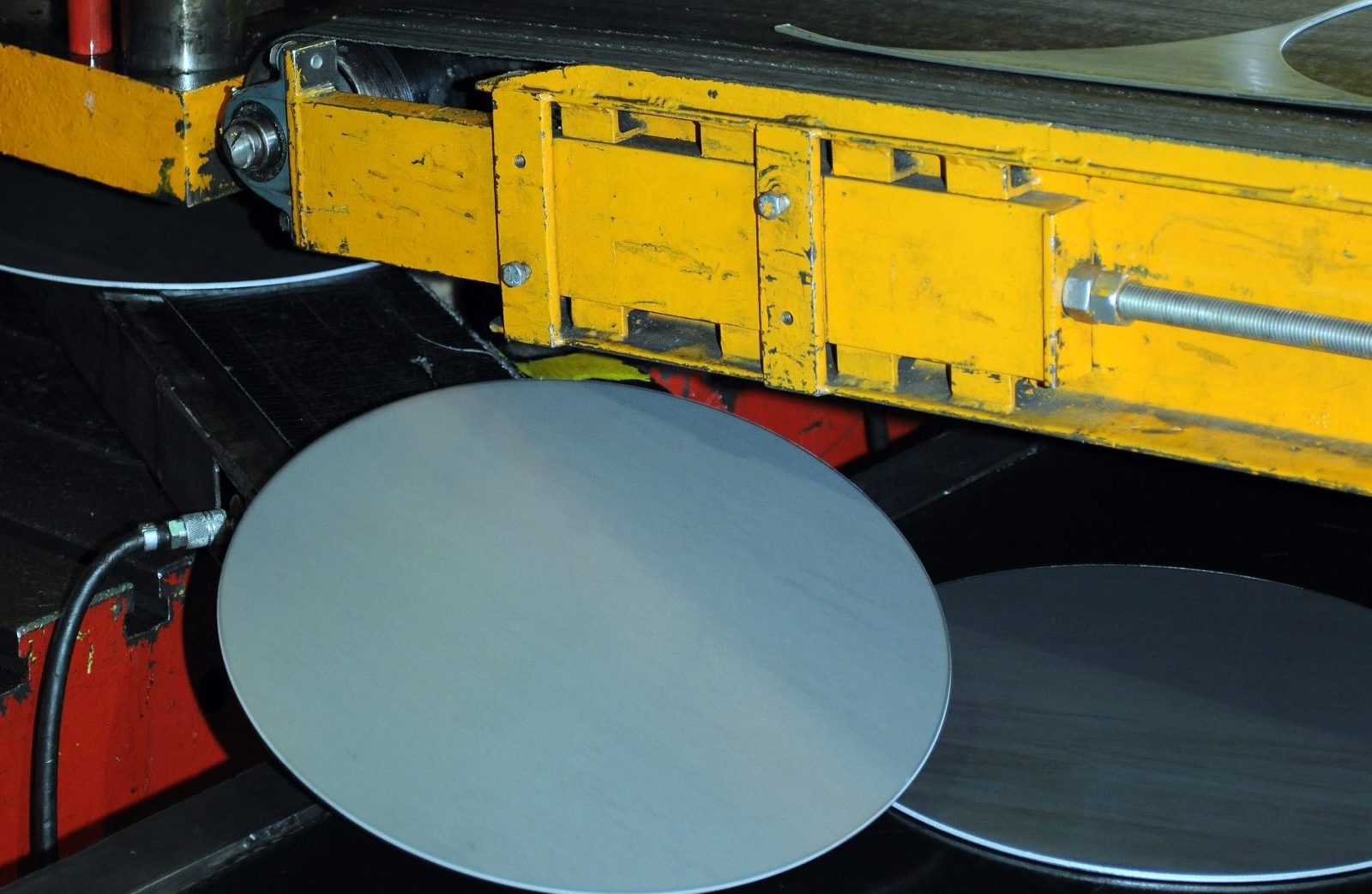

Edging

Edging at Heidtman Steel refines steel to deliver clean, precise edges that enhance performance and appearance. Whether it’s for improved safety, workability, or aesthetics, our advanced edging process ensures your steel meets the highest standards for quality and consistency.

About This Process

Edging is a steel finishing process that smooths and reshapes the edges of steel strips or coils, improving their precision, safety, and functionality. By eliminating sharp, uneven edges, the process prepares steel for further manufacturing while reducing risks during handling and processing. This step is crucial for applications requiring clean, consistent, and high-quality steel edges.

- Smooths and reshapes edges for safer handling and improved functionality.

- Enhances precision and dimensional accuracy of steel strips.

- Reduces edge cracks and imperfections, improving material quality.

- Compatible with a variety of steel grades and thicknesses.

Capable Locations

Min/Max Capability

.097 to .500

Key Characteristics

- Improved Safety: Removes sharp edges for safer handling and fabrication.

- Dimensional Precision: Ensures consistent edge profiles for better performance.

- Material Versatility: Effective on various steel grades, from hot rolled to coated products.

- Enhanced Aesthetics: Provides clean, professional edges for visible applications.

How is it Done?

- Material Feeding: Steel strips are fed into an edging machine.

- Edge Shaping: Specialized tooling smooths, rounds, or reshapes the edges to the desired profile.

- Deburring: Any residual burrs or imperfections are removed for a clean finish.

- Inspection: Edged steel is checked for quality and consistency before packaging.

Common Applications

- Automotive Industry: Steel strips used in precision parts and components.

- Manufacturing: Materials for stamped, welded, or fabricated products.

- Appliances: Steel for enclosures and panels requiring smooth edges.

- Construction: Edged steel for trim, framing, and structural components.

Benefits

- Consistent Quality: Delivers steel with smooth, precise edges for optimal performance.

- Improved Safety: Reduces risks associated with handling sharp or uneven edges.

- Enhanced Aesthetics: Clean edges improve the appearance of finished products.

- Material Efficiency: Minimizes waste by refining edges to exact specifications.

Why Choose Edging?

Edging is essential for steel that needs to meet the highest standards of safety, precision, and quality. At Heidtman Steel, our advanced edging process ensures your materials are ready to perform in any application with clean, consistent edges that enhance both functionality and appearance.