Galvanizing

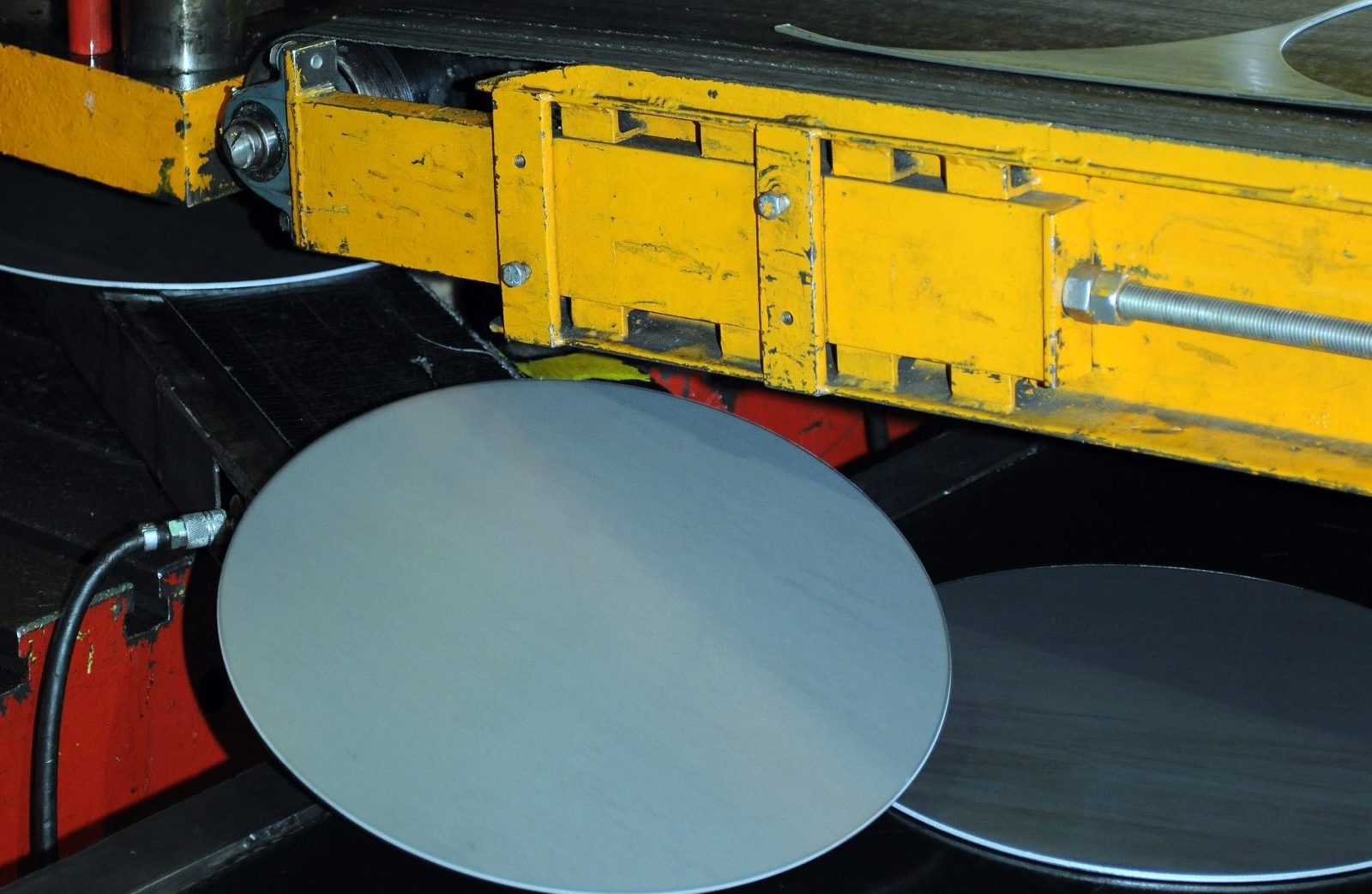

The galvanizing process at Heidtman Steel ensures superior protection for steel. With a durable zinc coating, we deliver corrosion-resistant steel that performs reliably in demanding environments, providing long-lasting, versatile solutions.

About This Process

Galvanizing is a process where steel is coated with a layer of zinc to protect it from rust and corrosion. At Heidtman Steel, this technique involves a meticulous hot-dip method, ensuring a uniform and durable coating. It’s essential for extending the life of steel in environments exposed to moisture, chemicals, or harsh weather, making it a trusted solution for industries like solar, automotive, and construction.

- Galvanizing coats steel with a protective zinc layer to guard against corrosion.

- Ensures a uniform coating through a hot-dip process for maximum durability.

- Extends steel lifespan in harsh environments, often lasting decades.

- Ideal for outdoor, automotive, solar, and construction applications.

Capable Locations

Key Characteristics

- Corrosion Resistance: The zinc coating provides excellent protection against rust, safeguarding steel in harsh conditions.

- Low Maintenance: Galvanized steel requires no upkeep, ensuring long-term performance without added costs.

- Durability: The galvanizing process creates a robust barrier, significantly increasing the steel’s lifespan.

- Versatility: Suitable for a wide range of industrial and commercial applications, from automotive to construction.

How is it Done?

- Cleaning: Steel is cleaned to remove dirt, oil, and scale, ensuring a pristine surface.

- Galvanization: Steel is dipped into a bath of molten zinc, forming a protective zinc layer.

- Cooling: The coated steel is cooled to solidify the zinc layer, enhancing durability.

- Final Processing: Sheets are cut, leveled, and finished to meet specific customer requirements.

Common Applications

- Automotive Industry: Parts exposed to moisture, such as panels and undercarriages, benefit from corrosion resistance.

- Construction: Roofing, siding, and structural steel for outdoor use, ensuring durability in harsh weather.

- Solar Industry: Frames and supports for solar panels, protected against rust in outdoor settings.

- Agriculture: Equipment and structures exposed to the elements, protected against rust.

- Appliances: Steel components needing corrosion resistance for long-term reliability.

Benefits

- Long-Lasting Protection: Extends the steel’s life in harsh environments, often lasting decades.

- Eco-Friendly: Galvanizing uses recyclable zinc and reduces the need for frequent replacements.

- Cost-Effective Solution: Reduces maintenance and replacement costs over time with no upkeep needed.

- Wide Application Range: Effective for industries requiring strength and weather resistance, like construction.

Why Choose Galvanizing?

When durability and corrosion resistance are critical, galvanizing is an unmatched solution. For steel that lasts in tough conditions, Heidtman Steel delivers exceptional quality through this essential process.