Leveling &

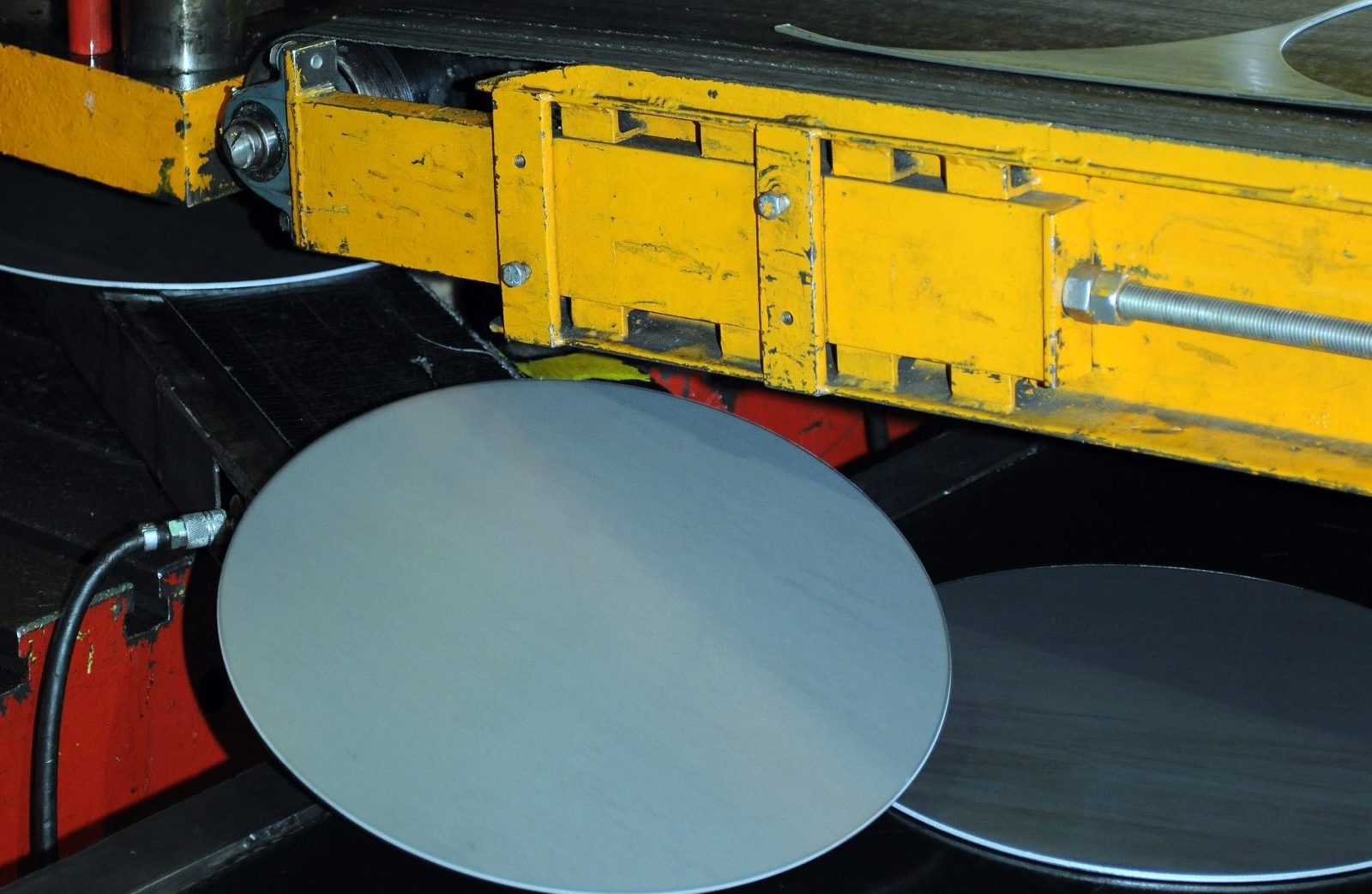

Stretcher Leveling

Leveling and Stretcher Leveling ensure your steel meets the highest standards of flatness and consistency. At Heidtman Steel, our advanced processes eliminate distortions and internal stresses, delivering perfectly flat, stress-free steel that improves quality and performance—ideal for industries where precision and reliability are critical.

About This Process

Leveling is a process that corrects surface distortions like waviness, bowing, and coil set to ensure flatness. Stretcher Leveling goes further by stretching the steel beyond its yield point to relieve internal stresses, delivering a flat and stress-free material that stays stable during fabrication. Together, these processes ensure steel performs consistently and meets the demanding standards of modern manufacturing.

- Corrects flatness defects such as waviness, bowing, or coil set.

- Stretcher leveling removes internal stresses, preventing warping during further processing.

- Enhances material quality for easier fabrication and long-term performance.

- Suitable for a wide range of steel types and thicknesses, including high-strength materials.

Capable Locations

Min/Max Capability

.015 to .500

Key Characteristics

- Improved Flatness: Eliminates surface distortions like waves and coil set.

- Stress-Free Material: Stretcher leveling relieves internal stresses, preventing warping during fabrication.

- Material Versatility: Effective for various steel grades, including advanced high-strength steels.

- Reliable Consistency: Ensures uniform results for superior performance in downstream applications.

How is it Done?

- Material Feeding: Steel sheets or coils are fed into the leveling or stretcher leveling machine.

- Flattening (Leveling): Precision rollers adjust pressure to correct flatness defects.

- Stretching (Stretcher Leveling): The material is gripped and stretched to exceed its yield point, relieving internal stresses and ensuring a permanent flatness.

- Inspection: Steel is checked for flatness, consistency, and stress-free quality.

- Finishing: The processed steel is prepared for further use or delivery.

Common Applications

- Automotive Industry: Body panels, chassis components, and precision parts that require stress-free steel.

- Construction: Roofing, siding, and structural materials needing long-term stability.

- Appliances: Flat, smooth steel for housings, enclosures, and stamped parts.

- Manufacturing: Steel for stamping, forming, and cutting with no risk of distortion.

Benefits

- Flatness Precision: Ensures steel meets exact flatness tolerances for high-performance applications.

- Stress Relief: Prevents warping or distortion during fabrication, ensuring long-term reliability.

- Improved Efficiency: Reduces material issues during processing, saving time and resources.

- Versatile Solutions: Suitable for industries with high-strength material needs or exacting flatness requirements.

Why Choose Leveling?

When precision and stability are critical, Heidtman Steel’s Leveling and Stretcher Leveling processes deliver. These advanced techniques produce perfectly flat, stress-free steel that’s ready to perform in the most demanding applications, ensuring quality and consistency every step of the way.