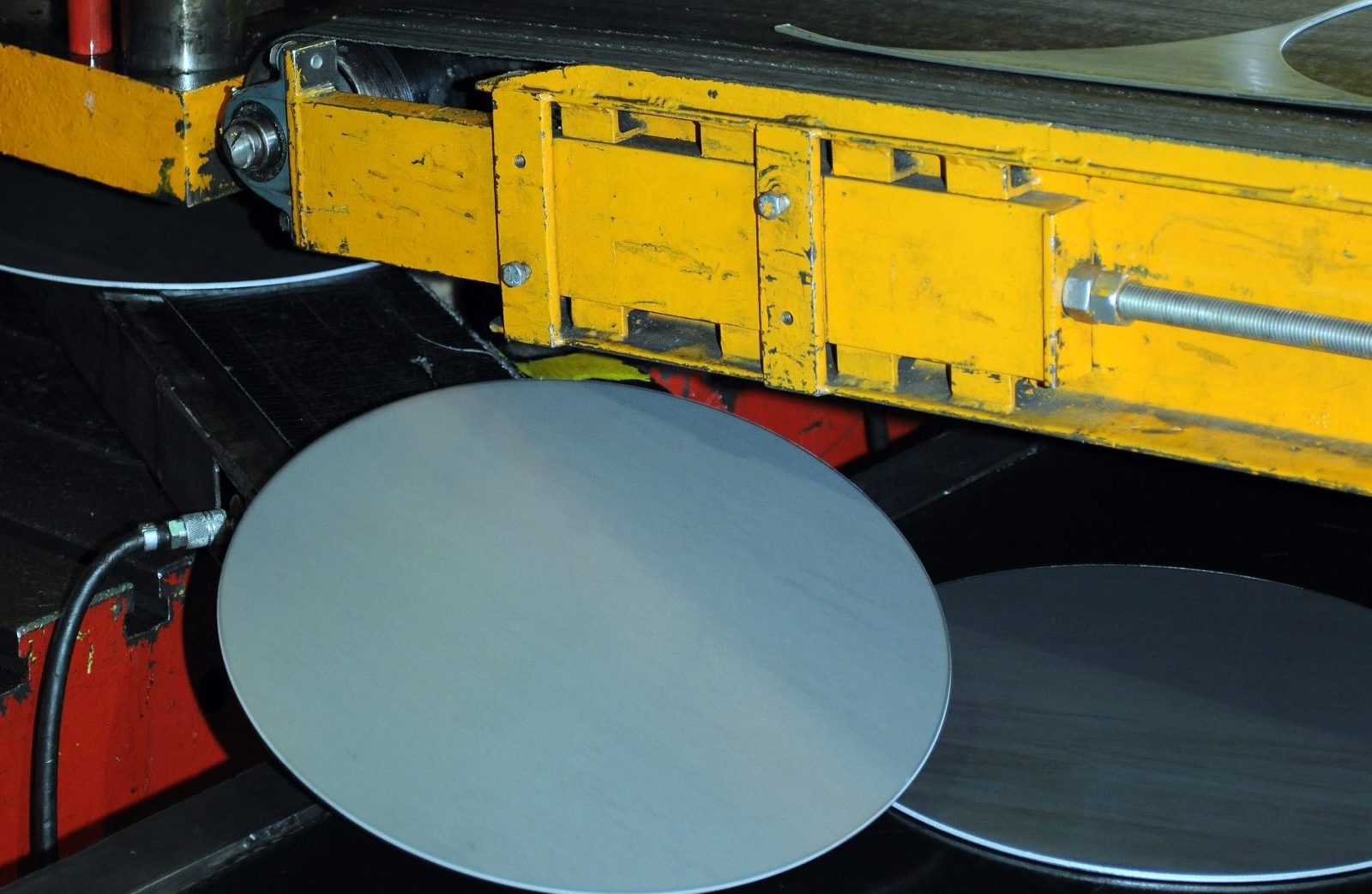

Slitting

Slitting is precision in motion, transforming steel coils into custom widths tailored to your exact specifications. At Heidtman Steel, our advanced slitting technology ensures clean edges, consistent dimensions, and minimal waste—delivering steel that’s ready for your next step in production.

About This Process

Slitting is a steel processing technique that involves cutting large steel coils into narrower strips. Using a series of rotary blades, the process ensures clean, accurate cuts while maintaining the structural integrity of the material. Slitting is essential for industries requiring steel in specific widths, ready for immediate use in manufacturing or fabrication.

- Cuts steel coils into narrower widths with precision and efficiency.

- Maintains tight tolerances for clean edges and consistent quality.

- Supports various steel types, including hot rolled, cold rolled, and coated materials.

- Increases efficiency by providing ready-to-use steel for downstream processes.

Capable Locations

Min/Max Capability

.015 to .530

Key Characteristics

- Precision Cutting: Ensures consistent widths and smooth edges for optimal performance.

- Material Versatility: Compatible with a range of steel grades and finishes.

- Customizable Widths: Delivers steel tailored to your exact specifications.

- High Volume Processing: Capable of handling large coils efficiently and accurately.

How is it Done?

- Loading: Large steel coils are mounted onto a slitter machine.

- Cutting: Rotary blades slit the coil into strips of the desired width.

- Recoiling: The cut strips are rewound into smaller coils for easy handling and transport.

- Quality Check: Slit coils are inspected for edge quality and dimensional accuracy.

Common Applications

- Automotive Industry: Steel strips for structural components and body parts.

- Manufacturing: Material for appliances, machinery, and tools.

- Construction: Trim, framing, and other applications requiring narrow steel strips.

- Metal Fabrication: Steel prepped for stamping, welding, and forming.

Benefits

- Maximizes Material Utilization: Reduces waste by cutting coils to precise dimensions.

- Speeds Up Production: Supplies steel ready for immediate use in manufacturing.

- Ensures Quality: Delivers clean edges and consistent widths for reliable results.

- Cost-Effective: Saves time and resources by eliminating the need for additional cutting.

Why Choose Slitting?

Slitting ensures you get steel that’s cut to your exact specifications, reducing waste and improving efficiency. At Heidtman Steel, we combine advanced technology and expertise to deliver slit coils that meet your needs with precision and reliability.