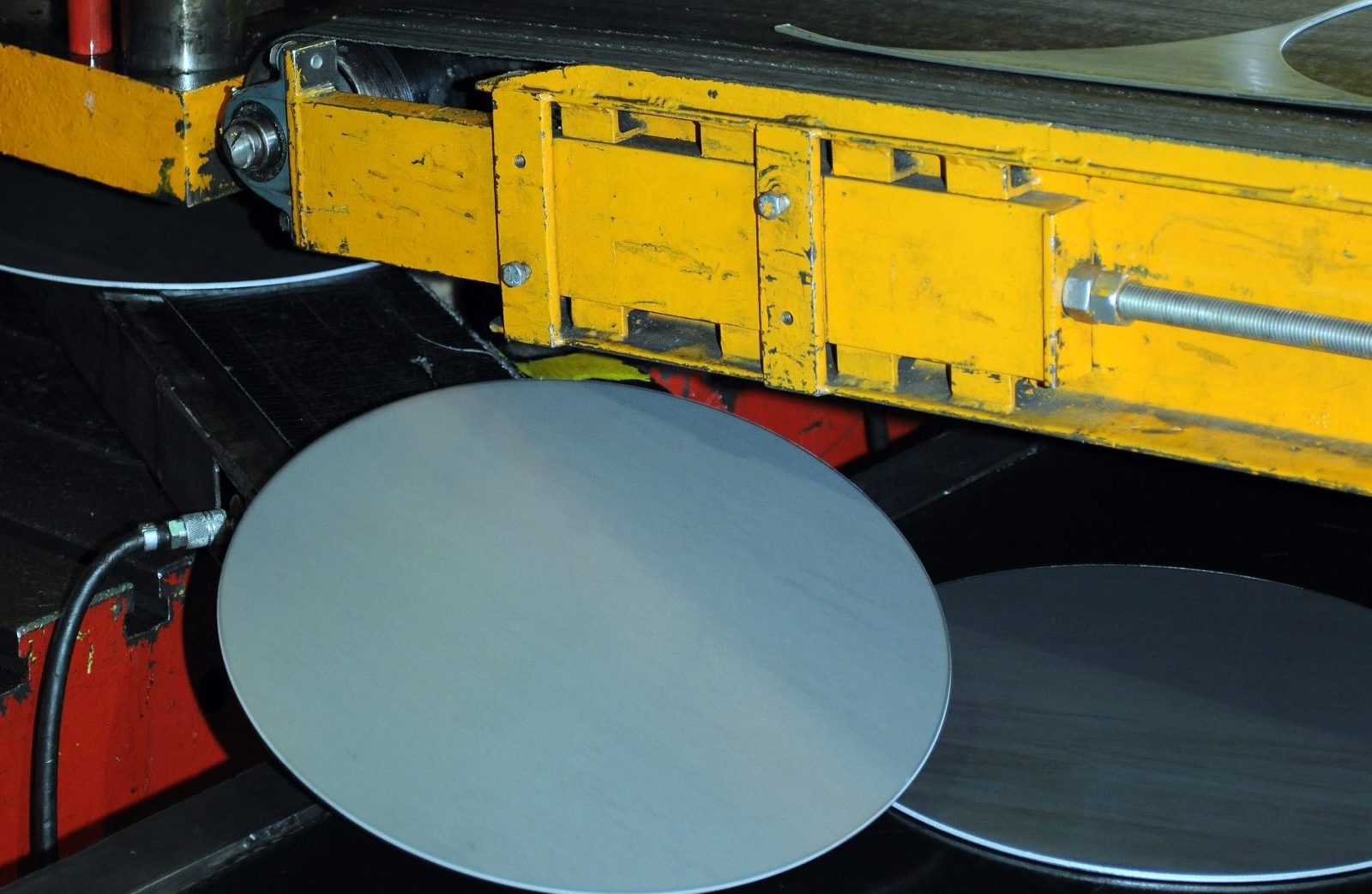

Tubing

The tubing process at Heidtman Steel delivers precision-crafted steel tubes tailored to meet diverse industry needs. With state-of-the-art equipment and rigorous quality control, we produce tubing that offers exceptional strength, dimensional accuracy, and versatility—perfect for applications ranging from automotive to construction.

About This Process

The tubing process creates precision steel tubes built for strength and versatility. At Heidtman Steel, we craft tubes for industries like solar, where torque tubes and racking support renewable energy systems, as well as structural and mechanical applications in construction and automotive, delivering performance you can trust.

- Creates high-quality steel tubes in various shapes, including round, square, and rectangular.

- Ensures tight dimensional tolerances for consistent performance.

- Accommodates a wide range of steel grades and finishes for applications like solar racking.

- Ideal for structural, mechanical, and industrial uses.

Capable Locations

Key Characteristics

- Shape Versatility: Produces round, square, and rectangular tubes to meet varied needs.

- Dimensional Accuracy: Ensures tight tolerances for consistent and reliable performance.

- Material Durability: High-strength steel ensures long-lasting performance in demanding environments.

- Custom Solutions: Tailored to meet the unique requirements of different industries.

How is it Done?

- Forming: Steel is rolled and shaped into the desired tube profile.

- Welding: The edges of the steel are joined using high-frequency electric resistance welding (ERW) for a strong, seamless finish.

- Sizing and Shaping: Tubes are passed through rollers to achieve precise dimensions and profiles.

- Finishing: Tubes are cut to length, tested for quality, and, if needed, coated for corrosion protection.

Common Applications

- Construction: Structural frameworks, scaffolding, and fencing.

- Automotive Industry: Exhaust systems, chassis components, and roll bars.

- Solar Industry: Torque tubes and racking for solar tracking and panel mounting systems.

- Manufacturing: Conveyor systems, furniture frames, and industrial machinery.

- Agriculture: Equipment, irrigation systems, and storage solutions.

Benefits

- Strength and Durability: Creates steel tubes that can withstand high stress and loads.

- High Precision: Ensures dimensional consistency for seamless integration into projects.

- Material Versatility: Supports a variety of steel grades for different applications.

- Efficiency: Delivers ready-to-use steel tubes for faster production cycles.

Why Choose Tubing?

With cutting-edge equipment and unmatched expertise, Heidtman Steel’s tubing process delivers high-quality steel tubes built to perform. From precise dimensions to superior durability, our tubing solutions provide the reliability and versatility industries depend on.